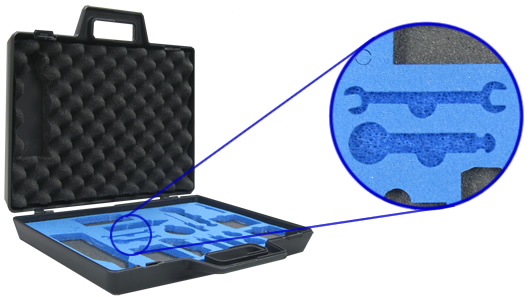

FOAM LASER TOOL KITTING SEATTLE WA

A Laser will help to organize your tools by shadowing them with tool foam. Utilizing tool foam can greatly reduce the amount of time that you spend looking for misplaced tools and increase your manufacturing and work place efficiency.

One of two basic techniques can be used for tool shadowing: First, is to completely cut out the outline and place a piece of contrasting colored foam on the back side. A heat gun or adhesive can be used to stick the two foam pieces together. The second method is to give the outline of the tool a fill and engrave away the shadow of the tool, like the zoomed in photo above.

The Simple Tool Foam Shadowing Process:

- Use a scanner/lightbox with a camera to import the tool image into your design software.

- Utilize the trace feature to create a vector outline of your tool.

- Send the cutting file to the laser with Kern’s easy to use Laser Printer Driver.